Enhancing Flow Control Efficiency for Petronas

Fleyenda’s success is built on real-world results—driven by innovation, precision, and strong client partnerships.

See how companies like Petronas achieved operational excellence with our solutions.

Inspired by their story? Share it and discover how Fleyenda can support your business too.

Reliable Flow Control for Transportation, Storage, and Distribution

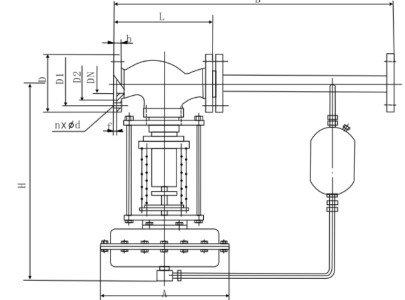

Fleyenda partnered with Petronas, a leading player in the oil and gas sector, to deliver advanced valve automation solutions for a critical upstream facility in Malaysia. To meet stringent safety and performance standards, we supplied a combination of electric and pneumatic actuated valves, along with precision globe control valves and customized actuators.

These components were engineered to withstand harsh environments, high pressure, and corrosive media typical of offshore and onshore installations. Our collaboration helped improve operational efficiency, reduce downtime, and streamline maintenance processes—contributing to a safer, more automated, and cost-effective infrastructure.

Fleyenda partnered with Petronas, a leading player in the oil and gas sector, to deliver advanced valve automation solutions for a critical upstream facility in Malaysia. To meet stringent safety and performance standards, we supplied a combination of electric and pneumatic actuated valves, along with precision globe control valves and customized actuators.

These components were engineered to withstand harsh environments, high pressure, and corrosive media typical of offshore and onshore installations. Our collaboration helped improve operational efficiency, reduce downtime, and streamline maintenance processes—contributing to a safer, more automated, and cost-effective infrastructure.

Project Highlights

Successfully implemented valve automation across multiple production lines

Delivered corrosion-resistant and ATEX-certified actuators

Reduced manual intervention through remote monitoring solutions

Supported Petronas with post-installation training and technical guidance

Challenge

Petronas was operating a critical upstream facility in Malaysia, where harsh conditions, including high pressure, corrosive media, and remote locations, posed serious challenges to efficiency and safety. The manual control systems in place led to increased downtime, higher maintenance demands, and limited real-time response capabilities—impacting operational continuity and cost-effectiveness.

Petronas was operating a critical upstream facility in Malaysia, where harsh conditions, including high pressure, corrosive media, and remote locations, posed serious challenges to efficiency and safety. The manual control systems in place led to increased downtime, higher maintenance demands, and limited real-time response capabilities—impacting operational continuity and cost-effectiveness.

Study

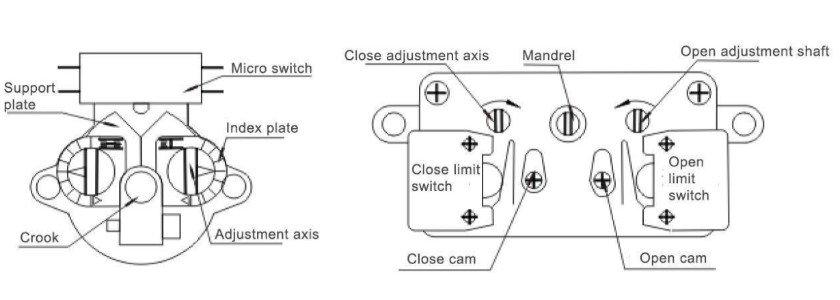

Fleyenda collaborated closely with Petronas engineers to develop a tailored automation solution. We supplied a range of electric and pneumatic actuated valves, globe control valves, and custom-built actuators designed to perform reliably in extreme environmental conditions.

Key features included:

> Corrosion-resistant materials suited for offshore environments

> Integration-ready actuators with remote monitoring capabilities

> ATEX-certified components ensuring compliance with industry safety standards

> On-site technical support and commissioning guidance

Results

Petronas was operating a critical upstream facility in Malaysia, where harsh conditions, including high pressure, corrosive media, and remote locations, posed serious challenges to efficiency and safety. The manual control systems in place led to increased downtime, higher maintenance demands, and limited real-time response capabilities—impacting operational continuity and cost-effectiveness. Petronas was operating a critical upstream facility in Malaysia, where harsh conditions, including high pressure, corrosive media, and remote locations, posed serious challenges to efficiency and safety. The manual control systems in place led to increased downtime, higher maintenance demands, and limited real-time response capabilities—impacting operational continuity.

Fleyenda collaborated closely with Petronas engineers to develop a tailored automation solution. We supplied a range of electric and pneumatic actuated valves, globe control valves, and custom-built actuators designed to perform reliably in extreme environmental conditions. Fleyenda collaborated closely with Petronas engineers to develop a tailored automation solution. We supplied a range of electric and pneumatic actuated valves, globe control valves, and custom-built actuators designed to perform reliably in extreme environmental conditions.

Fleyenda collaborated closely with Petronas engineers to develop a tailored automation solution. We supplied a range of electric and pneumatic actuated valves, globe control valves, and custom-built actuators designed to perform reliably in extreme environmental conditions. Fleyenda collaborated closely with Petronas engineers to develop a tailored automation solution. We supplied a range of electric and pneumatic actuated valves, globe control valves, and custom-built actuators designed to perform reliably in extreme environmental conditions.